Non-woven medical textiles are advantageous for applications in diverse healthcare because they provide many substantial benefits. One such advantage is their compact, breathable design that makes it easier for air to flow through so your skin stays cool and comfortable. And non-woven fabrics are absorbent and provide for applications that need to absorb or release moisture. Additionally, these are inexpensive and disposable materials that prevent cross-contamination and keep patient care aseptic. SMMS Nonwoven Fabric For Protective Clothing.

Quality control is crucial for non-woven medical textiles, which influence the safety and comfort of patients. Xingdi adopts benchmark and rigorous testing system to make sure all the items are of high quality and performance. From the choice of raw materials to production processes, be sure that all steps are meticulously controlled and traceable in every respect. And with quality assurance that you can take to the doctor, Xingdi offers healthcare professionals nonwoven medical textiles that perform just as they should and would expect.

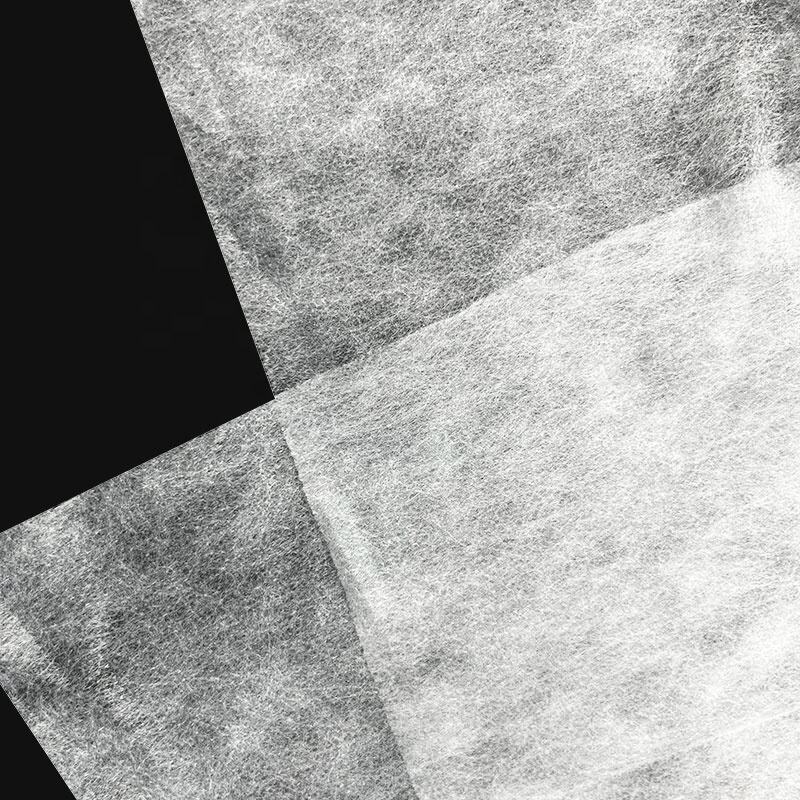

non woven medical product making machine Non woven fabric medical products are being used more and more widely due to their perfect filtration nature, there are 2 ply tie-on strips type mask usage (weight-20--25gsm.qrst),3-ply ear loop strip useage(weight20—30gsm),50gms round cap usageand1818 dustproof gear( design weight-70gram square, machine-make size3.5cmx4cm). These textiles are produced without actually weaving with the yarns being mechanically intertwined to form a fabric that is strong and hardwearing. Xingdi is a professional non woven company that sells medical textile. These new fabrics are revolutionizing the field by offering an economical and effective option for healthcare professionals.

One of the largest benefits of using non woven medical textiles is that it can prevent the spread of bacteria and viruses. These are breathable fabrics, but they will stand up to the abuse of medical procedures. They have a lot of potential uses from surgical gowns to wound dressings. Xingdi’s non woven medical textiles helping reduce the risk of infection in hospitals and healthcare.

Non woven medical textiles are not only changing the way that the health care industry works, but also the ways in which the medical industry and public perceive of it. It takes a lot of water and energy to create traditional textiles, whereas non woven textiles can be made with less waste and resources. Xingdi is environmentally conscious and always seeking ways to minimize their carbon footprint.

Medical non woven applications: - Wound healing Key products for wound-healing wovens include dressing retention and wet to dry sponges. These fabric can easily absorb liquids and let air through, which is conducive to healing. Xingdi’s wound dressing non woven are skin friendly, soft and comfortable, suitable for the care of sensitive patients.

Another important characteristic of non woven medical textiles is that they help prevent the spread of infection. Xingdi's non-woven fabrics are medicated with an antimicrobial agent that can inhibit the growth of disease transmitting microorganisms in the healthcare setting. This additional level of protection is vital to help keep patients and medical staff safe and healthy.

Our quality control is supported by in‑line monitoring instruments and precision testing equipment—including fiber‑size analyzers, electronic water‑penetration meters, strength testers, and wear testers—ensuring every batch meets stringent performance and consistency standards.

In 2021, we launched a new 3.2‑meter SSSS production line with an annual capacity of 12,000 tons, enabling the manufacture of ultra‑fine, multi‑layer fabrics tailored for high‑end sanitary, medical, and hygiene applications.

With over 12 years of industry experience, our facility spans 20,000 square meters, operates 8 advanced production lines, and achieves an annual output exceeding 96,000 tons—providing robust supply capabilities for high‑volume orders.

As a recognized provincial high‑tech enterprise, we focus on medium‑to‑high‑end PP spunmelt non‑wovens, utilizing Japanese‑sourced spinnerets and German calendering technology to produce premium‑grade SS, SMS, SMMS, and multi‑layer fabrics.