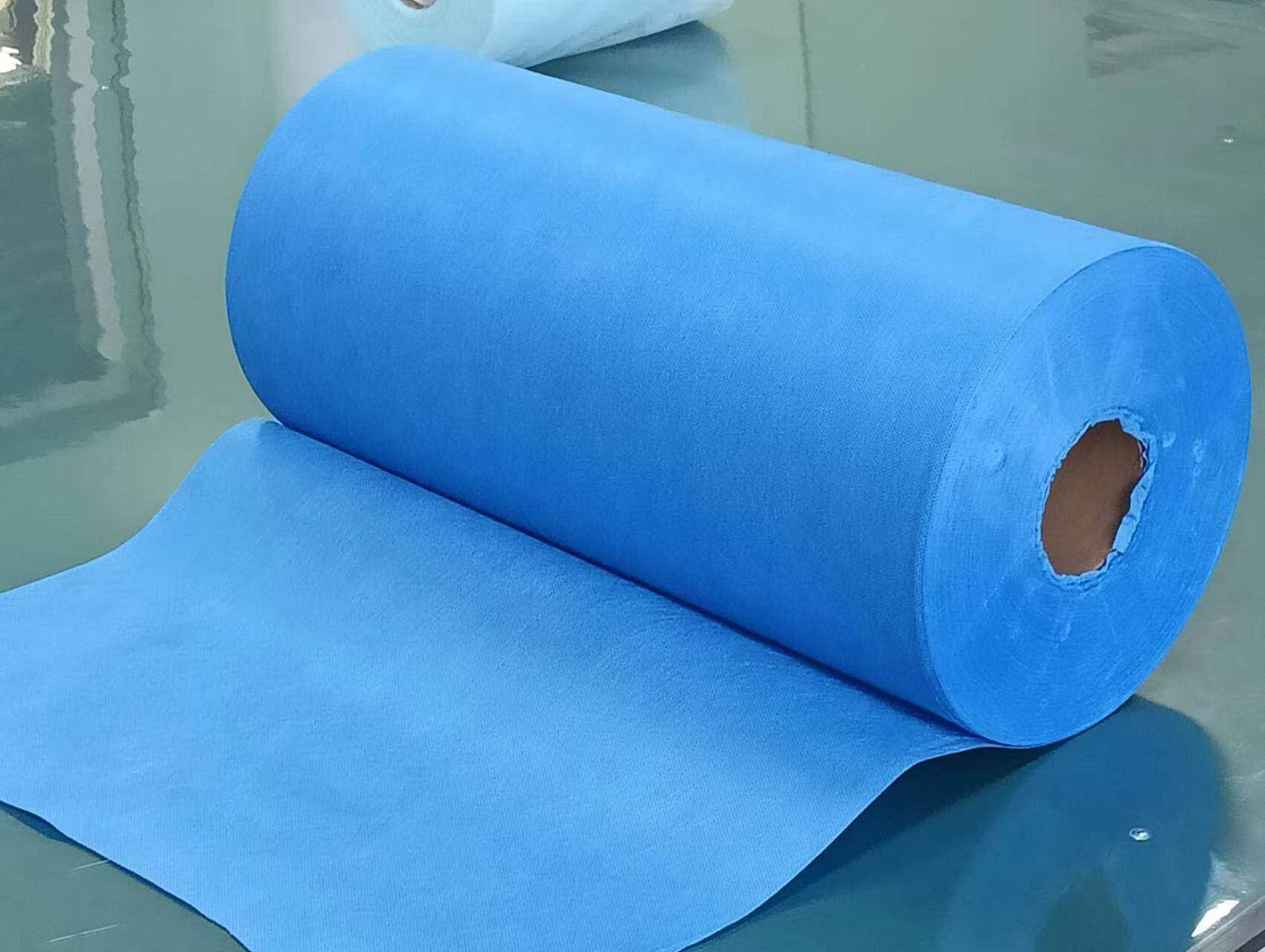

High quality non woven bag material for long serving life

As for non-woven bags, in order to make them strong and able to last long high quality material should be employed. Xingdi provides high quality non-woven bag material that is very durable and highly wear resistant, meaning you can trust your bags won't fade over time. The material is handpicked to provide the best mixture of strength and flexibility; therefore it can be used in an array of applications.

So where can you look for the best non woven polaroid photography bag material supplier?

Best non-woven bag material suppliers This is challenging to find the best non-woven bag material manufacturers like Xingdi that having full control of production. As a reliable source for all your non-woven bag material needs with superior quality and ability to meet a high standard. Whether you need materials for shopping bags, promotional totes or other types of non-woven bag, Xingdi brings it to you. Their assortment of materials is so extensive that you can always find the products to fit your requirements. And their team of specialists is there to help every step of the way, so you know that whatever material you choose for your latest project, it will be the very best. Don't compromise on quality or materials - choose Xingdi for your non-woven bags and get the highest level of quality and durability available!

Selecting the best non-woven bag type for your brand:

When choosing the perfect non-woven bag material for your company, a few things need to be taken into account. First, consider the reason for the bag. Are you toting groceries, canning jars or using it as a promotional give-away? There are different grades of non-woven materials, some stronger than others and you want to select based on the use of the bag. Second consider the design and printing options. Some types of non woven fabrics are more suitable for bright and rich colours, as well as intricate patterns, while the printing performance may be constrained on other kinds. And finally, the environmental impact of the material. Opt for eco-friendly alternatives that are recyclable or biodegradable to share your brand values.

Popular designs and patterns of non woven bag material:

There are always new styles and patterns coming out in the non-woven bag world. A common trend is the use of bold and visually appealing designs, including geometric images, floral motifs and abstract figures. These designs can be beautiful pieces that make the page pop. Or for the ultimate non woven bag more and more people are choosing metallic touches like gold or silver foil printing to give their bags a luxury feel. Moreover, environmentally-friendly designs such as nature-based prints and earth tones continue to be popular as the world becomes further conscious in sustainability and caring for Mother Earth. Now, think of adding these models and designs to your non-woven bags for grabbing more group.

Best material for non-woven bag for promotional events:

The selection of the non-woven bag material is particularly important to enhance personalization for promotional events. Xingdi Provide many kinds of non-woven products for different Halloween promotions, including strong and durable polypropylene bags and light weight shopping bags. They feature custom options to include your brand logo or message, which is great for escalating the popularity of your brand. What’s more, Xingdi non-woven bags come in all different shapes and sizes – tote bags, drawstring backpacks and anything else you’ll need for any promotional event. Whether you are looking for to promote your new product, increase brand recognition, or thank your customers, Xingdi’s non-woven bag material is the perfect solution for a wide range of non-woven bags with unique PMS colors.

With over 12 years of industry experience, our facility spans 20,000 square meters, operates 8 advanced production lines, and achieves an annual output exceeding 96,000 tons—providing robust supply capabilities for high‑volume orders.

As a recognized provincial high‑tech enterprise, we focus on medium‑to‑high‑end PP spunmelt non‑wovens, utilizing Japanese‑sourced spinnerets and German calendering technology to produce premium‑grade SS, SMS, SMMS, and multi‑layer fabrics.

Our quality control is supported by in‑line monitoring instruments and precision testing equipment—including fiber‑size analyzers, electronic water‑penetration meters, strength testers, and wear testers—ensuring every batch meets stringent performance and consistency standards.

In 2021, we launched a new 3.2‑meter SSSS production line with an annual capacity of 12,000 tons, enabling the manufacture of ultra‑fine, multi‑layer fabrics tailored for high‑end sanitary, medical, and hygiene applications.