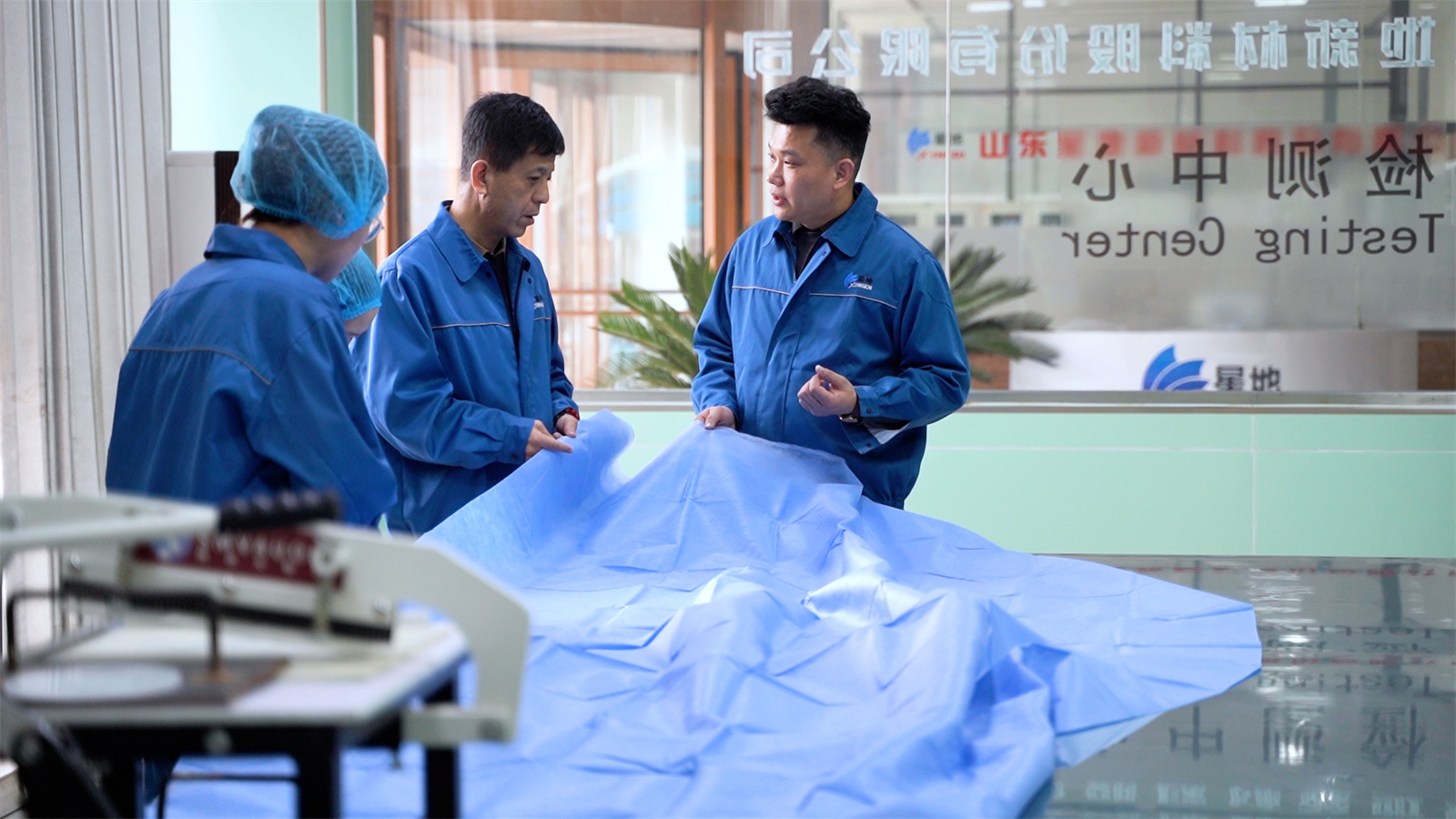

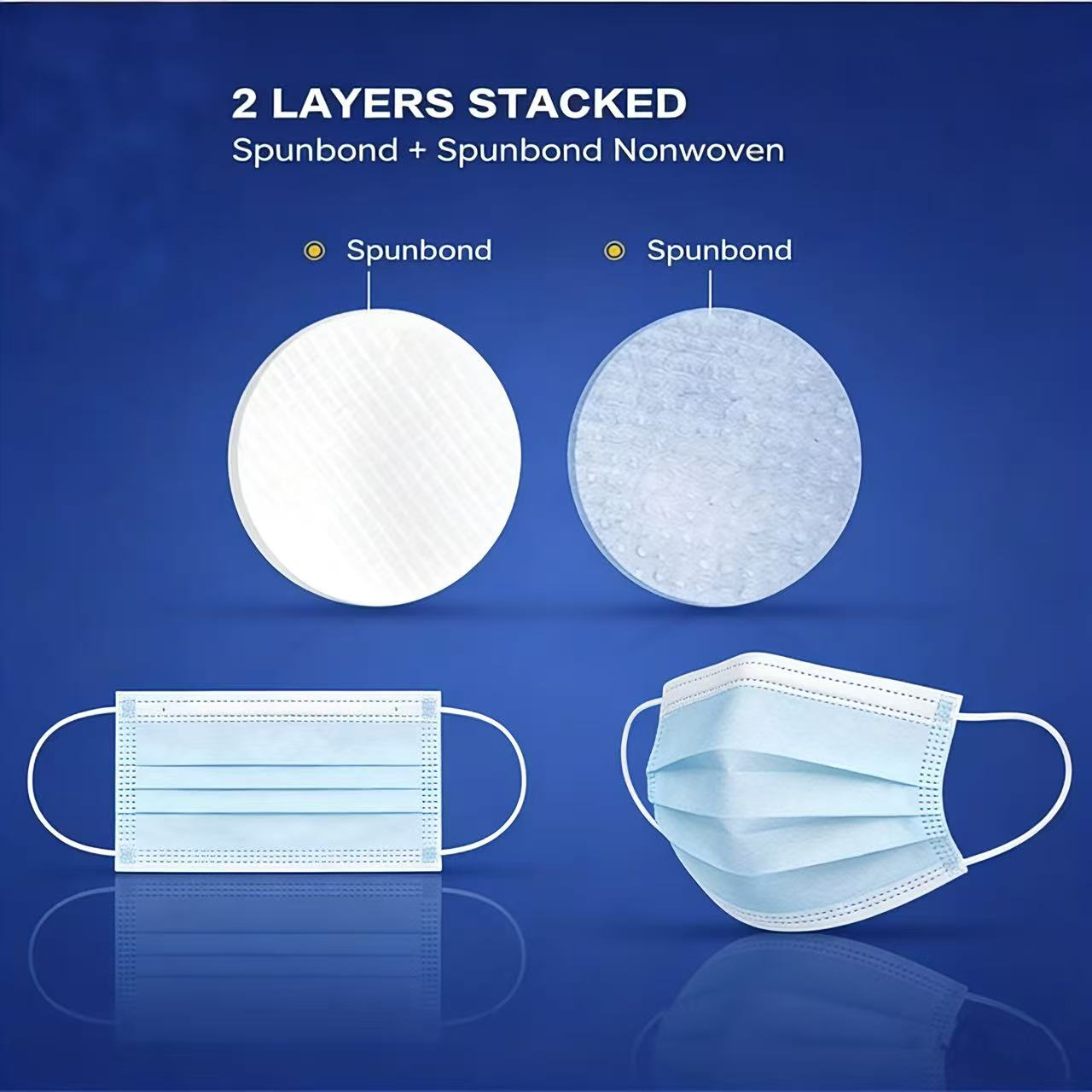

Developed by Shandong Xingdi New Material Co., Ltd., the 25-30gsm 100%PP SS Spunbond Non Woven Fabric Roll is a core functional material specifically tailored for three-layer disposable masks, widely applied in household and medical scenarios. Crafted from high-purity polypropylene chips, it adopts advanced double-layer spunbond (SS) technology and hot-calendering bonding process, a signature of the company’s production strength. This ensures stable structural performance, consistent product quality, and full compliance with scenario-specific usage requirements, aligned with the firm’s focus on hygienic and medical nonwoven materials.

With grammage precisely controlled between 25-30gsm, it strikes an optimal balance between structural firmness and air permeability—critical for three-layer mask structures. As the inner and outer protective layers, it perfectly caters to both daily household protection and basic medical prevention needs, leveraging the company’s expertise in SS spunbond fiber arrangement and soft handfeel optimization.

Its core selling points are threefold: Firstly, the medical-grade PP material is non-toxic and skin-friendly, complying with Chinese national standards and the standards of most other countries. Secondly, the double-layer spunbond structure enhances barrier performance, effectively blocking dust, droplets and impurities while maintaining breathability. Thirdly, the uniform web structure and excellent tensile strength adapt seamlessly to high-speed mask production lines, minimizing material waste during cutting and lamination.

As a direct manufacturer with a complete quality management system certified to ISO 9001, Shandong Xingdi New Material Co., Ltd. supplies this cost-effective SS spunbond fabric to global mask brands and manufacturers, specializing in materials for three-layer disposable masks. Backed by advanced inspection instruments and years of experience serving top hygiene brands, it delivers reliable protection for both household and medical use with premium, scenario-adapted materials.

|

Item Name |

Ss PP Nonwoven Fabric |

|

Material |

Polypropylene(PP) |

|

Width |

0.1m-3.2m |

|

Weight

|

10-70gsm (recommend 20-25gsm) |

|

Feature |

Waterproof, Mothproof, Skin-friendly, Breathable, Anti-Static, Anti-Bacteria, Anti-Pull, Hydrophilic |

|

Pattern |

Sesame, Dot |

|

Application |

Medical Product: Medical Facemask;Shoe Cover; Bouffant Caps, etc. |

|

Roll length |

As Buyer's Requirement |

|

Color |

White,Blue,Green,Yellow,Black,etc. |

In the large-scale production of ordinary civil disposable masks and medical disposable masks, 25-30gsm SS nonwoven fabric has become the preferred base material for manufacturers due to its balanced performance and high cost-effectiveness. Produced by a fully automated spunbond process, its color can be flexibly adjusted. In addition to conventional white and blue, a variety of color systems can be customized to meet the diverse appearance needs of civilian masks. The outer SS spunbond layer has strong wear resistance, which can effectively block dust, pollen and other impurities in the air. At the same time, it has excellent air permeability, without obvious stuffiness when worn, fully suitable for various civilian scenarios such as daily commuting, supermarket shopping and outdoor activities.

In terms of mass production adaptability, SS spunbond nonwoven fabric rolls are evenly wound with uniform specifications, which can be directly connected to mainstream automated mask production lines. It is accurately compounded with ear loops and nose wires through ultrasonic welding technology, with no additional loss during processing, greatly improving production efficiency. The inner 25-30gsm SS spunbond layer adopts a fine fiber structure, which is soft, skin-friendly and non-adhesive to the skin. Even if worn for a long time, it is not easy to cause allergies or discomfort, suitable for all groups of people such as the elderly and children. The material is non-toxic, environmentally friendly and disposable, and can control costs through large-scale production, perfectly balancing protective effect and public consumption capacity. Disposable masks are one of the most consumed products in the protective equipment market, widely available in various retail channels such as pharmacies, e-commerce platforms, and convenience stores. Our SS non-woven fabric will contribute to the production of every mask.

1. Who are we?

We are based in Shandong, China, start from 2013,sell to South America(60%), South Asia(30%), Eastern Europe(10%).

2. How can we guarantee quality?

We provide free fabric samples and quality inspection reports. Before mass production, we support small batch trial orders for machine testing.

3. What are your export advantages?

We have 11 years of export experience and support multiple language services including English, Korean, Japanese, Spanish, and Portuguese, providing you with a one-stop service.

4. What are our trade terms?

Usually FOB, CFR, CIF, EXW, Express Delivery

5. What is the difference between S, SS, and SMS nonwoven?

S = single‑layer spunbond

SS = two‑layer spunbond (stronger than S)

SMS = spunbond + meltblown + spunbond (has filtration layer).

SS is often used for mask inner/outer layers, while SMS is used for surgical masks.

6. What certifications do you have for SS nonwoven?

We have SGS, ISO9001, ISO14001, and other certifications.

Thank you for your interest in our products. We specialize in high-quality SS Spunbond Nonwovens (25-30gsm) specifically designed for disposable mask production. Our fabrics offer excellent tensile strength, breathability, and barrier protection, ensuring stable performance on high-speed production lines. Suitable for both medical and civil mask applications, our materials are the ideal choice for manufacturers seeking reliable quality at competitive prices.

To celebrate our partnership and reward every valued client, we are launching exclusive tiered promotions! upon their initial purchase, helping you reduce costs while testing our product quality. For our loyal partners, based on your cumulative order volume, making long-term cooperation more cost-effective. Additionally, for large-volume purchases, we provide extra bulk discounts to further boost your profit margins. Take advantage of these limited-time offers to cut raw material costs without compromising on product quality.

We offer a comprehensive one-stop 24/7 service to support your business needs. Our team of experts is ready to provide you with tailored procurement solutions and technical support., and confirm your eligibility for new customer or repurchase discounts. Simply leave us a message, and we will lock in your exclusive discount immediately. Don't miss this opportunity to secure the best price for your nonwoven fabric supply.

We look forward to building a long-term, mutually beneficial partnership with you. Let us help you reduce costs and increase efficiency.

Contact Email: [email protected]

Contact Phone: +86-15553709566

Website: www.worldwoven.com