|

Prodcuts |

Spunbond Nonwoven Fabric |

|

Raw Material |

100% Virgin Polypropylene |

|

Nonwoven Technics |

Spun-Bonded |

|

Width |

100mm-3200mm |

|

weight |

10g-70g |

|

Color |

Custom Color |

|

Application |

Disposable 3PLY medical facemsk,Tapabocas,Mascaras |

|

MD Tensile strength |

≥11 N/25mm |

|

CD Tensile strength |

≥9N/25mm |

|

MD Elongation |

≥110% |

|

CD Elongation |

≥ 115% |

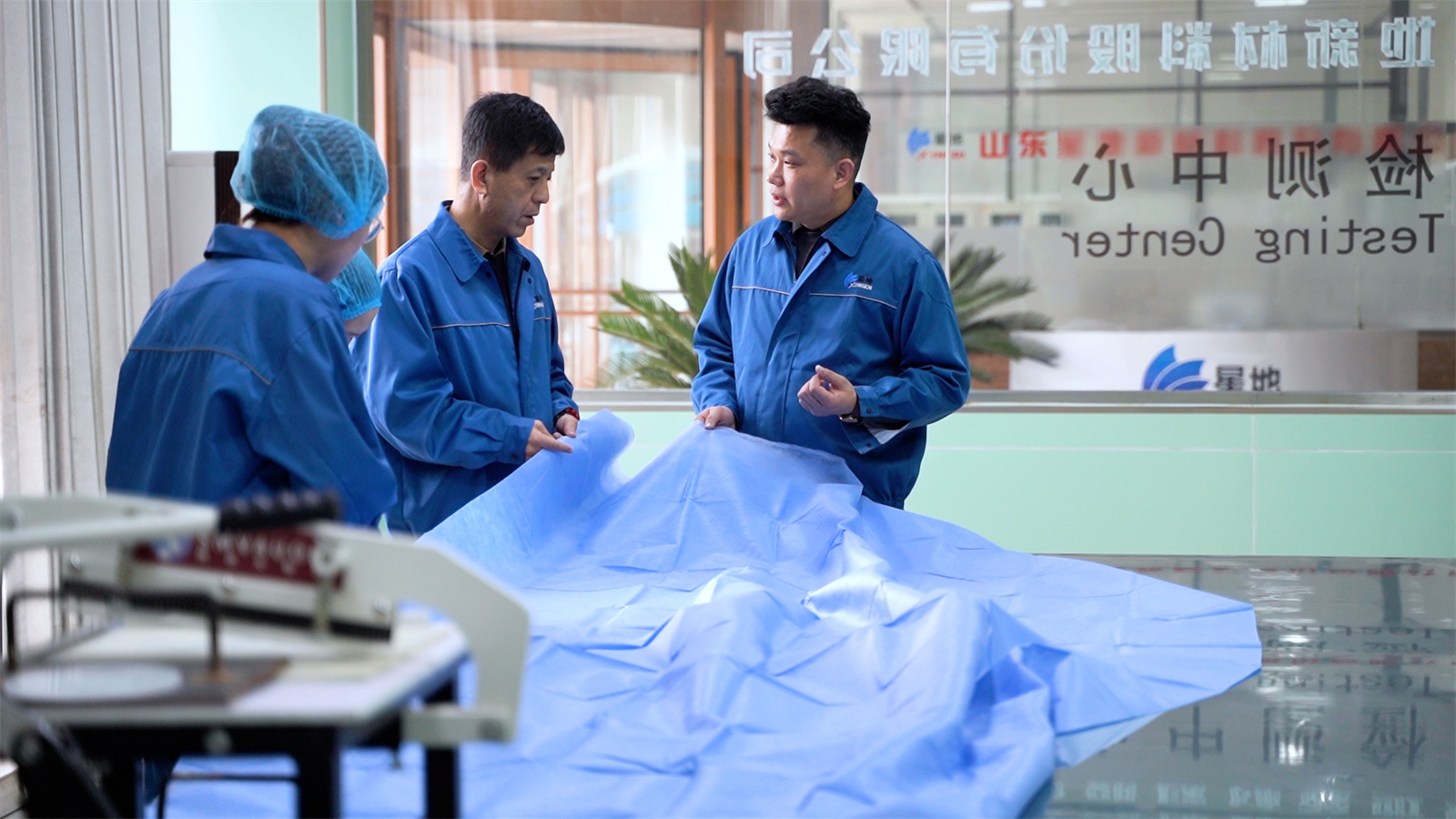

This SS spunbond non-woven fabric stands out with exceptional customization capabilities, perfectly tailored to the diverse production demands of disposable masks across medical, daily protection and industrial sectors. It supports flexible specification adjustments, with width customizable from 100mm to 3200mm to precisely match all types of production lines—from small-scale manual equipment to large automatic assembly lines with high-speed lamination systems. This eliminates secondary cutting procedures, minimizes material waste and significantly boosts production efficiency compared to standard fabrics, while optimizing cost control for enterprises. Professional functional treatments are available to cater to distinct layer requirements: hydrophilic treatment for the inner layer adopts modified polypropylene monomers to achieve efficient water absorption, enabling rapid absorption of moisture and sweat to keep the skin dry, while water-repellent treatment for the outer layer forms a reliable barrier against liquid splashes, fully aligning with YY/T 0691 medical standards for surgical masks. Multi-color customization further empowers brands to achieve differentiated appearance design, with excellent color fastness to resist fading during processing and use, enhancing market competitiveness. Additionally, the fabric can be customized with different surface textures, such as dot-bonded or smooth finishes, to match specific mask design needs.

Crafted from 100% virgin polypropylene compliant with ISO standards, it adopts advanced double-headed spunbond technology with precise temperature control to form a uniform continuous filament structure. Controlled within the 25-30gsm golden weight range via professional online monitoring systems, the fabric balances lightweight texture and structural sturdiness, withstanding ultrasonic welding and earloop bonding without breakage. Its permanent anti-static function, achieved by adding high-performance antistatic agents during production, effectively prevents dust adsorption, while zero fiber shedding ensures breathing space cleanliness, meeting strict hygiene norms for medical devices.

Featuring fine 2-3D microfibers, it delivers ultra-soft skin-friendly touch even for sensitive skin, with a low friction coefficient to reduce skin irritation. Scientific fiber arrangement enhances air permeability while maintaining basic particle blocking capability, effectively solving stuffiness issues of long-term wearing. Beyond masks, it is widely applicable in hygiene materials such as diaper covers and feminine hygiene product liners, medical consumables including isolation gown linings and surgical drape substrates, as well as packaging materials for electronic components. Its excellent anti-static and chemical stability also make it suitable for outdoor protective products, showcasing versatile value across industries.

Boasting functional modification and comfort enhancement, 25-30gsm SS spunbond nonwoven fabric gains unique advantages in ordinary civil and medical disposable masks, especially for users pursuing better wearing experience and long-lasting protection. As the core material for mask inner and outer layers, it is made of 100% polypropylene via double-layer spunbond process, offering basic barrier protection and structural support. It can extend application scenarios through antibacterial modification and ultra-soft treatment, balancing practicality and comfort.

In medical scenarios, modified SS spunbond nonwoven fabric boosts masks’ long-term protection. Antibacterial powder-added outer layers inhibit bacteria, reducing the burden on meltblown layers and extending protection duration. Medical-grade ones undergo strict dust-free treatment, with a cotton-soft, non-irritating touch. Matching widened elastic ear loops, they suit 8-hour continuous wear for medical staff, widely used in outpatient and ward care. Sterilized by ethylene oxide, they meet medical hygiene standards.

In civil scenarios, ultra-soft SS spunbond fabric elevates comfort. Its optimized inner layer is delicate and cloud-soft, reducing skin friction and avoiding itching or acne, ideal for children, sensitive skin users and long commutes. The outer layer has good water repellency and breathability, blocking dust, droplets and splashes without stuffiness. It can be hydrophilic or antistatic treated, fitting food processing and electronic workshops to prevent pollution.

It is highly compatible with meltblown and activated carbon layers, and pairs well with 3D design to enhance facial fit. Non-toxic, eco-friendly and disposable, it supports large-scale production and color customization, meeting retail and medical bulk purchase needs as an all-round material balancing protection, comfort and cost-effectiveness.

1. What is the MOQ for SS nonwoven fabric?

For white non-woven fabric, we have no MOQ, but for colored non-woven fabric, our MOQ is 20 tons.

2. Can we custom-make non-woven fabric in a specific color?

Of course. We can adjust the colors according to your needs to meet your color requirements

3.What types of fabric can we provide for masks?

We can provide you with the inner and outer layers of the mask, only spunbond non-woven fabric

4. What specifications of non-woven fabric can we provide?

We can provide various types of SS/SSS/SSSS/SMS non-woven fabrics with widths ranging from 100-3200mm, weights from 10-70gsm, and either hydrophilic or hydrophobic properties.

5. Can we provide samples?

A: Our factory can provide FREE samples but does not bear the freight.

6. What products are our SS non-woven fabrics suitable for manufacturing?

A:Our high-quality SS non-woven fabric can be used in products such as masks, fluffy hats, foot covers, agricultural covers, packaging bags, and clothing linings. For specific details, please consult customer service.

Thank you for your interest. As your trusted , we don't just sell fabrics; we engineer solutions. One of our core focus is on SS Spunbond Nonwovens (25-30gsm) for disposable mask production. We understand that every application is unique, which is why we specialize in . Whether you require enhanced , superior, or specialized properties, our R&D team and production team can modify the fabric structure to meet your specific technical specifications.

We offer a seamless to support your production around the clock. Our experts provide comprehensive procurement solutions, ensuring you get the right material at the right price. We are committed to being your reliable partner in the nonwoven industry, offering flexibility and innovation to help your products stand out in the market.

Ready to test the quality for yourself? We offer a to ensure full transparency and confidence in our products. Additionally, take advantage of our to evaluate the texture, strength, and performance firsthand before placing a bulk order. Don't miss this opportunity to experience our premium quality and service.

For customized quotes, technical details, or to request your free sample, please reach out today. We look forward to hearing from you!

Contact Person: [email protected]

Contact Phone: +86-15553709566

Website: www.worldwoven.com