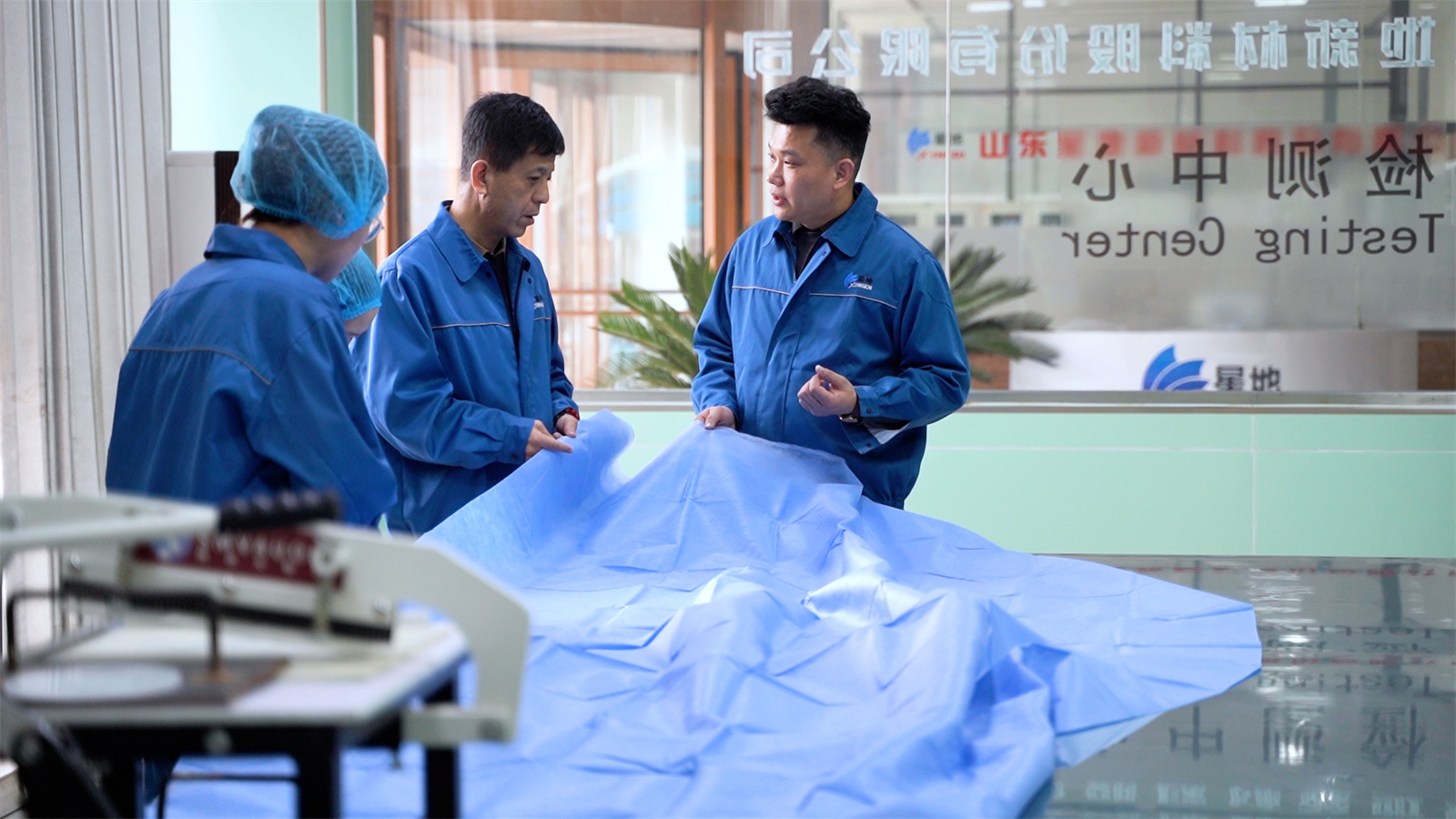

Shandong Xingdi New Materials Co., Ltd. was established in December 2013. Located in Zoucheng, Shandong Province, the hometown of Confucius and Mencius, we are a provincial-level high-tech enterprise specializing in the production of mid-to-high-end PP spunmelt non-woven fabrics for personal hygiene care and medical care.

The company is equipped with domestically advanced SS/SSSS/SMMS non-woven production lines and 3D embossing production lines, as well as a fully enclosed production workshop, with an annual output of 27,000 tons. Backed by a professional management team and over ten years of production experience, we have been supplying high-quality non-woven fabrics with water-repellent, hydrophilic, super-soft, elastic and cool-feeling properties to the high-end medical and sanitary materials industries. Our products are widely used in the production of sanitary napkins, diapers, surgical gowns, isolation gowns, protective clothing and anti-smog masks.

Specifically designed for mask production, our SS spunbond non-woven fabric is made from carefully selected high-purity polypropylene raw materials, ensuring light weight, ultra-soft texture, excellent breathability and skin-friendly performance. Meanwhile, it has remarkable waterproof, tear-resistant and non-deformable properties, making it highly durable in practical applications. The fabric is fully customizable in color (including white, blue, green and other custom shades) and grammage (ranging from 10 to 80gsm), and is perfectly suitable for medical masks, civil masks and other sanitary products. It complies with SGS and Oeko-tex certification standards, providing reliable quality assurance for the upgrading of daily necessities.

With its fine fiber structure, the fabric can effectively block particles of ≥0.3 microns and bacteria. When used with a spunbond layer, it further enhances the filtering performance of

|

Item |

SS Nonwoven Fabric |

|

Raw Material |

100% Polypropylene |

|

Width |

Within 3.2m |

|

Weight |

9-70GSM |

|

Color |

Custom color |

|

Application |

Hygiene Product: Sanitary Napkin, Baby & Adult Diaper, Under Pad, etc.Medical Product: Face Mask, etc. |

|

Feature |

Good strength and elongation; non-toxic; breathable; hydrophilic or hydrophobic; anti-bacterial, etc. |

|

Roll Length |

Buyer's Requirement |

|

Certification |

SGS, MSDS, ISO |

This SS spunbond non-woven fabric is specifically developed and optimized for the mass production of disposable masks, adhering to high-quality standards from raw material selection to processing. Crafted from 100% high-grade polypropylene (a material renowned for its non-toxicity, stability and excellent mechanical properties), it adopts advanced double-headed spunbond technology—an innovative process that ensures uniform fiber distribution and tight interweaving. This technological advantage endows the fabric with superior structural integrity compared to conventional single-headed spunbond products, making it the preferred core material for both inner and outer layers of disposable masks in the medical, daily protection and industrial fields.

The product weight is strictly controlled within the golden range of 25-30gsm through precise weight monitoring systems during production. This well-balanced specification achieves an ideal combination of lightweight texture and reliable structural strength: it is thin enough to avoid a bulky wearing experience, yet sturdy enough to withstand the rigorous processes of mask folding, ultrasonic welding and earloop bonding. This perfect adaptation to three-layer mask production lays a solid foundation for both the protective performance and long-term wearing comfort of the final products.

In terms of core performance, the fabric boasts exceptional quality thanks to refined production control. It features uniform and flawless fiber spraying without uneven thickness or broken filaments, presenting a smooth and delicate surface that avoids irritation to the skin. The continuous filament structure formed by the double-headed spunbond process enhances its tear resistance significantly, preventing fabric breakage during mask processing and use. Meanwhile, it is equipped with an efficient permanent anti-static function, which not only avoids fiber adsorption of dust, lint and other impurities during production and wearing but also eliminates static discomfort for users. Importantly, the fabric maintains zero fiber shedding throughout its entire service life, ensuring the cleanliness and safety of the breathing space and meeting the strict hygiene requirements of medical and daily protection scenarios.

Its ultra-high softness, derived from the fine and flexible polypropylene fibers, delivers an excellent skin-friendly experience, even for sensitive skin. Coupled with strong air permeability—achieved through scientific fiber arrangement that allows smooth air circulation while blocking particles—it effectively solves the common pain points of traditional masks such as stuffiness and skin friction after long-term wearing, greatly improving overall wearing comfort.

The flexible specification customization capability fully covers diverse production needs of enterprises. The width can be flexibly adjusted and customized within the range of 100-3200mm, accurately matching various types of mask production lines and equipment, from small-scale manual machines to large-scale automatic production lines. This eliminates the need for secondary cutting, reduces material waste, and greatly improves production efficiency and cost control. In addition, it supports professional functional treatments such as hydrophilicity and water repellency: hydrophilic treatment is suitable for the inner layer to quickly absorb moisture and sweat, while water repellent treatment is applied to the outer layer to block liquid splashes, perfectly catering to the different functional requirements of mask inner and outer layers. At the same time, multi-color customization services are provided to help enterprises realize differentiated appearance design of mask products and enhance market competitiveness.

Beyond being the core material for inner and outer layers of disposable masks, this SS spunbond non-woven fabric has a wide range of application scenarios. It is widely used in hygiene materials, medical consumables, as well as packaging materials.

1. Disposable Civil Masks

SS spunbond non-woven fabric is a preferred outer and inner layer material. Its dense, uniform fiber structure effectively blocks dust, pollen, droplets and other external particles, while its smooth, skin-friendly surface avoids friction and irritation during long-term wear. With excellent air permeability ensuring unobstructed breathing, it solves the problem of stuffiness from prolonged daily use. As the inner layer, its moisture-absorbing property quickly soaks up exhaled moisture and sweat, keeping facial skin dry and comfortable, and reducing bacteria growth from dampness.

2. Disposable Medical Surgical Masks

This fabric performs excellently as both outer and inner layers. The outer layer has good water repellency, effectively resisting droplet and body fluid infiltration to prevent cross-contamination, meeting medical-grade barrier requirements. The soft, lint-free inner layer avoids secondary pollution to the medical environment, protecting medical staff. Its stable physical properties adapt to high-speed production lines (up to 400 pieces/min), guaranteeing consistent quality and efficiency.

3. Children's Disposable Masks

Its lightweight flexibility fits kids’ delicate facial contours without oppression. Non-irritating and non-toxic, it meets children’s skin safety standards, filtering daily pollutants while ensuring comfort and reducing kids’ resistance to wearing masks.

4. Daily Public Place Masks (Supermarkets, Subways, Offices)

It balances protection, comfort and cost-effectiveness, enabling manufacturers to produce affordable products for public daily needs.

Widely used in disposable masks, SS spunbond non-woven fabric boosts manufacturers’ product quality and competitiveness with stable performance, meeting civil and medical market requirements. It also suits inner/outer layers of disposable face shields and respirators, expanding application scope and providing reliable material support for the hygiene and protection industry.

1. Are you a trading company or a manufacturer?

We are a professional manufacturer of PP spunbond non-woven fabrics, covering an area of more than 20,000 square meters with over 400 workers. We have rich experience in import and export, and our products are sold to domestic and global markets.

2. Can you custom-make non-woven fabric in a specific color?

Of course. We can adjust the colors according to your needs to meet your color requirements.

3. What types of fabric can you provide for masks?

We can provide you with the inner and outer layers of the mask, which are spunbond non-woven fabrics.

4. What are your export advantages?

We have 11 years of export experience and support multiple language services including English, Korean, Japanese, Spanish, and Portuguese, providing you with a one-stop service.

5. Can SS nonwoven be used for face mask outer layer?

Yes, SS nonwoven is commonly used as the outer layer of disposable masks because it is water-repellent and provides good strength.

6. How long is your guarantee time for after-sales service?

As long as our company is existing, after-sales service is valid.

Thank you for browsing our product page! We specialize in SS spunbond nonwovens for disposable masks, with core specifications of 25-30 gsm. It perfectly fits the production of civil and general medical protective masks, serving as the preferred raw material for mask factories and medical device enterprises. Boasting excellent air permeability, flexibility and barrier properties, the product passes strict quality inspections, stably adapting to high-speed mask production lines and ensuring the protective performance and wearing comfort of finished products.

We offer 24/7 one-stop services to meet your urgent needs. Whether you are a start-up or a mature enterprise, we provide tailored procurement solutions based on your production capacity, budget and quality requirements, with dedicated staff following up the whole process from selection to logistics, reducing your costs efficiently.

Widely used for inner and outer layers of disposable masks, it can be customized in parameters for different protection levels. We strive to be your reliable long-term supply chain partner, helping you gain an edge in the market.

For more details, accurate quotes or customized plans, feel free to contact us. We will respond promptly with professional answers to advance cooperation.

Contact Person: [email protected]

Contact Phone: +86-15553709566

Website: www.worldwoven.com

We look forward to cooperating with you for mutual benefits and building a high-quality protective equipment supply chain.