Polypropylene spunbond in agriculture PP spunbonded is currently used as crop covers, weed control fabric and greenhouse insulation. Due to its UV resistance and water permeability, it proves to be quite an excellent choice for securing crops from strong wind or rain and various pests. It is true for farmers, who can use the material to keep the plants protected for a long time and still let air and moisture through!

Polypropylene spunbond provides businesses with a more affordable alternative to production. In addition, durable construction of the knife-grade silicone results in a lightweight product that users can enjoy and easily take on-the-go without adding fill weight. Organizations can go with this material in order to make cuts on costs, without ever sacrificing over the quality.

Apart from being cost-effective, polypropylene spunbond is an eco-friendly fabric. It is also recyclable and reusable which reduces waste, promoting sustainability downstream. Companies who want to lead the way in promoting green initiatives will find it advantageous to include this material in their products; thus offering consumer goods in compliance with industry regulation and environmentally conscious buyers.

Additionally, polypropylene spunbond is easy to handle, which increases production assivite. Due to its uniform construction and even quality, it is suitable for automatic production technology and can improve productivity while reducing labor. It reduces the steps and simplifies handling, enabling companies to utilize it in their production lines for a seamless workflow.

Influentially, polypropylene spunbond is an adaptable and reasonably priced material with several advantages for different types of businesses. Between its relevance in health care as a protective material, and strength properties for agriculture, packaging etc., there is no doubt xiamen acrylic processing is a great value addition to any company that needs to improve the quality of their products while increasing efficiency at the same time. Add polypropylene spunbond to your business and enjoy the benefits it provides.

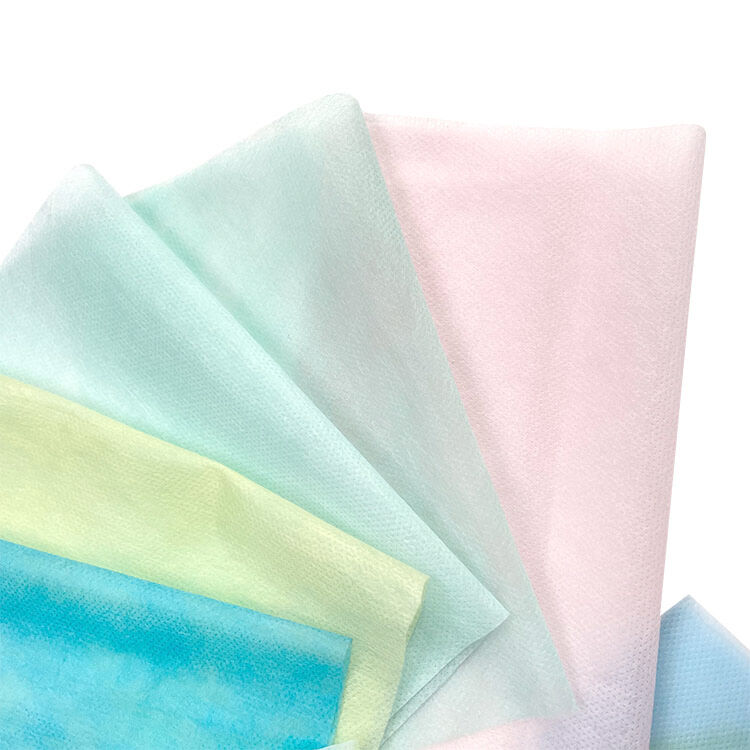

Polypropylene spunbond is a common material choice for bulk buyers since it's tough, strong and versatile. Polypropylene spunbond is comprised of extremely fine continuous filaments of polypropylene that are laid in a random pattern so that this web will not ravel or fray. The material can be withstood, whatever you throw at it. For wholesale buyers looking for strong and long lasting products the Meindl Desert Fox is a well priced choice which more than delivers. What’s more, polypropylene spunbond is lightweight and easy to use, which makes it a great option to use in bulk production or manufacturing processes. Due to its outstanding properties and diverse range of applications, polypropylene spunbond is the ideal material for wholesale purchase when it comes time for buyers to look for high quality materials at great value.

A few factors you should consider when looking to purchase high-quality polypropylene spunbond at competitive prices. First of all, you wanna find a supplier with the history making good quality product. Xingdi is a manufacturer of polypropylene spunbond with the completion lines from S, SS, SSS to SMS. Second is to think about how they are producing the product. Xingdi takes technology as the pilot, produces polypropylene spunbond that go on reel well with both its quality and prices. Lastly, talk to your suppliers so you can get a good deal on a bulk rate. Collaborating closely with Xingdi, Wholesale purchasers can find high-quality polypropylene spunbond at competitive pricing and for a seamless process that ensures their products are trustworthy as well as affordable.

As a recognized provincial high‑tech enterprise, we focus on medium‑to‑high‑end PP spunmelt non‑wovens, utilizing Japanese‑sourced spinnerets and German calendering technology to produce premium‑grade SS, SMS, SMMS, and multi‑layer fabrics.

In 2021, we launched a new 3.2‑meter SSSS production line with an annual capacity of 12,000 tons, enabling the manufacture of ultra‑fine, multi‑layer fabrics tailored for high‑end sanitary, medical, and hygiene applications.

Our quality control is supported by in‑line monitoring instruments and precision testing equipment—including fiber‑size analyzers, electronic water‑penetration meters, strength testers, and wear testers—ensuring every batch meets stringent performance and consistency standards.

With over 12 years of industry experience, our facility spans 20,000 square meters, operates 8 advanced production lines, and achieves an annual output exceeding 96,000 tons—providing robust supply capabilities for high‑volume orders.