show code on cursor in the input box ( 0 / 3000 ) Other Products Perforated nonwoven cloth Contact Now Character:Cost-effective and versatile, perforated nonwovens are used as packaging materials. One of the advantages of using this fabric is that it is breathable, which can prevent moisture from accumulating and mold from forming on products. Furthermore, nonwoven perforated fabric is light in weight and easy to manipulate as needed for use in packaging applications requiring a lightweight material. This is also a tear-resistant fabric, so all of your pack items will remain safe while in transportation and storage. Another benefit of perforated non woven fabric is that it is cheap to produce, so for companies wanting to spend less on packaging materials this is an economical option.</p>

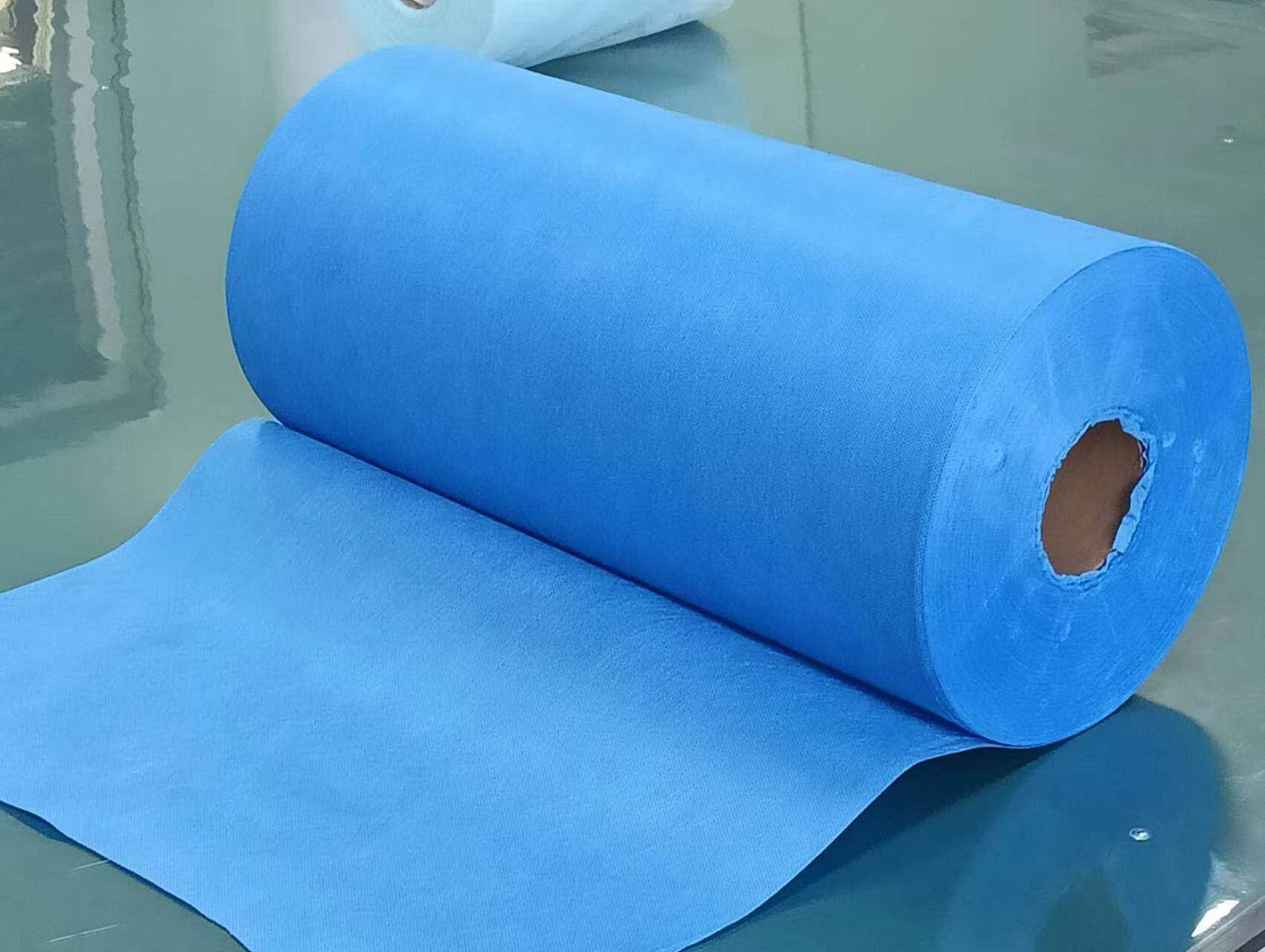

Your Best Source for Perforated Non Woven Fabric from the Mask Material Manufacturer If you are searching for the best deals on perforated non woven fabric, look no further than Xingdi. The range offered by us includes Non-Woven Fabric Roll / Bag.Rich and competent R&D sifter compact, fast change-over, low noise, smooth performance, are the advantage of this bag making machine. If you want the fabric to use for another thing, let’s say, industrial and packaging purposes, Xingdi got that too. Based on our quality and service as a broad-based vision, to provide customers with the best quality perforated non woven fabric at the most reasonable price. Get in touch today to find out about our range of products and how we can help supply your fabric.

What is Perforated non woven fabric? These voids permit the air to easily pass through the fabric making it ideal for uses in which good air circulation is crucial. In most industries, no matter it is medical, automobile or home furnishing industry, healthy and comfortable work environment can't be reached without good air circulation.

In addition to its clothing applications, perforated nonwovens can enable air to pass through the material and prevent the wearer from overheating, helping keep them feeling cool and comfortable. This class of material is commonly found in medical applications such as bandages, or wound dressings which work to aid healing by both promoting the breathability of a wound and minimizing risk for infection. Perforated non woven fabric can also be employed in automotive applications, as in car seat and headliner to promote air circulation and avoid moisture accumulation and odor formation.

One the perforated non woven fabric for agriculture has a big advantage in that it allows air and water to get through, but blocks UV rays. This helps to create a conducive environment for plants to grow, thereby improving crop health and increasing yield. What's more, since the fabric has holes in it, let your garden breath and helps drain water to prevent damage to plants or-- use side by side for faster results.

If you are looking for perforated non woven fabri factory or wholesaler, and want to buy perforated non woven fabri from china, please feel free to contact us. Our company offers a variety of good quality perforated non woven fabric for many applications.

As an experienced perforated non woven fabric manufacturer, we will offer you a professional service and the best quality that will meet your need. Whether you are looking for fabric for clothing, wound care dressing products, car interiors or any other hot air bags application, we have the solution.

Our quality control is supported by in‑line monitoring instruments and precision testing equipment—including fiber‑size analyzers, electronic water‑penetration meters, strength testers, and wear testers—ensuring every batch meets stringent performance and consistency standards.

As a recognized provincial high‑tech enterprise, we focus on medium‑to‑high‑end PP spunmelt non‑wovens, utilizing Japanese‑sourced spinnerets and German calendering technology to produce premium‑grade SS, SMS, SMMS, and multi‑layer fabrics.

With over 12 years of industry experience, our facility spans 20,000 square meters, operates 8 advanced production lines, and achieves an annual output exceeding 96,000 tons—providing robust supply capabilities for high‑volume orders.

In 2021, we launched a new 3.2‑meter SSSS production line with an annual capacity of 12,000 tons, enabling the manufacture of ultra‑fine, multi‑layer fabrics tailored for high‑end sanitary, medical, and hygiene applications.