More versatile applicaton:elastic non-woven fabric is widely used in various industries. Xingdi is focus on produce non woven fabricand we have been supplying best products for our customers from all over the world. Stretch knit fabrics are stretchable, durable and relatively inexpensive, so they can be used for a number of things.</p>

Non-woven fabrics with high elasticity have advantages in application of daily necessities. The stretchabilities can provide flexibility and a comfort in which various garments, diapers, medical apparatuses and the like may be made. The stretchiness of these fabrics allow for a tighter fit and better performance of the finished goods. Elastic nonwoven fabrics are also very strong, wear resistant and can be long lasting so they save manufacturers and consumers money. Furthermore, these materials are lightweight and breathable for ease of use in a wide range of applications. In summary, inelastic nonwoven fabrics used in wholesale items have a number of advantages that make the final products more comfortable and useful.</p>

Because of their versatile and excellent performance, elastic nonwoven fabrics are widely used in multiple fields. In medical industry, these materials are commonly used in medical gowns, surgical face masks and wound dressing because of its comfortability and breathability and stretch-ability. Elastic nonwoven fabrics are the source material for diapers, sanitary napkins and adult incontinent products within personal hygiene applications due to their softness, absorbency, flexibility and so forth. These sorts of textiles are also used in the automotive sector for car interiors, headliners and even seat coverings since they can withstand wear and tear very well, are low-maintenance and cost-effective. Additionally, the furniture and bedding industries use stretchable nonwoven fabrics for upholstery materials, mattress covers and pillows due to their comfortable feel and durability appearance. In general the elastic nonwoven fabrics are popular in many industries as a highly useful and effective material.</p>

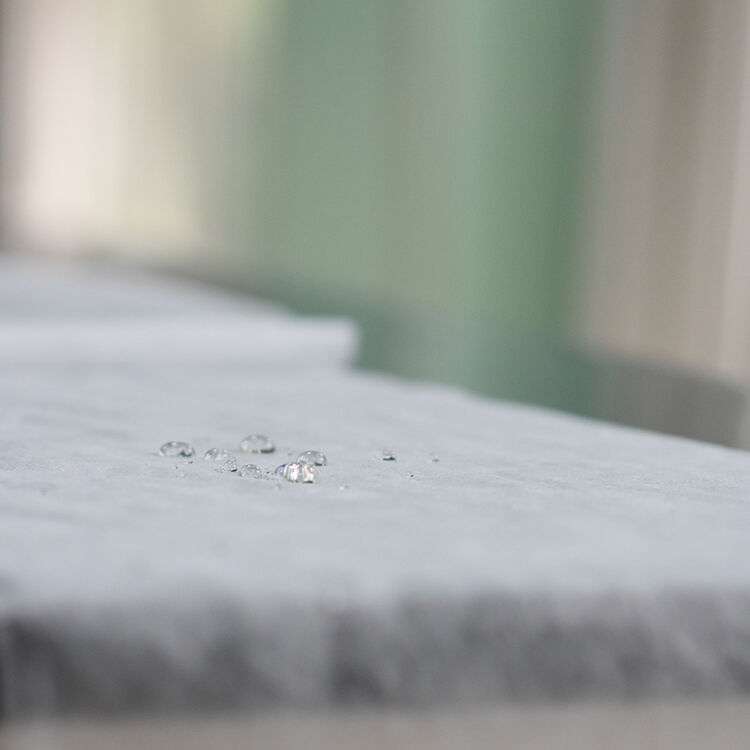

At Xingdi, we have perfectly elastic nonwoven that is superior to the competition. Our elastic nonwoven was constructed from premium material, which is reusable and resilient. Unlike other non wovens, our elastic nonwoven is able to stretch and recover back to its original shape, making it ideal for many applications.</p>

If you want to buy elastic nonwoven products, please click in detail in the website of Xingdi. Our elastic nonwoven is offered at competitive prices because we believe it shouldn't just be for big businesses. No matter what the size of your order, we have you covered with all the materials for your business.</p>

When you select Xingdi for your wholesale elastic nonwoven needs, you can be confident knowing that you are receiving the best in material quality and that our plant will live up to or exceed your expectations. We developed our durable non woven today to stand up to the wear and tear of daily use, an ideal option for businesses that need sturdy materials at a great price.</p>

When selecting a provider for your elastic nonwovens, there are several factors to keep in mind so that you can be sure you are getting the best quality materials for your business. First up, determine the reputation of the seller and learn about the success record in delivering a good quality product to their customers. Xingdi has a history of high-quality export elastic non-woven fabric products to global businesses.</p>

In 2021, we launched a new 3.2‑meter SSSS production line with an annual capacity of 12,000 tons, enabling the manufacture of ultra‑fine, multi‑layer fabrics tailored for high‑end sanitary, medical, and hygiene applications.

As a recognized provincial high‑tech enterprise, we focus on medium‑to‑high‑end PP spunmelt non‑wovens, utilizing Japanese‑sourced spinnerets and German calendering technology to produce premium‑grade SS, SMS, SMMS, and multi‑layer fabrics.

Our quality control is supported by in‑line monitoring instruments and precision testing equipment—including fiber‑size analyzers, electronic water‑penetration meters, strength testers, and wear testers—ensuring every batch meets stringent performance and consistency standards.

With over 12 years of industry experience, our facility spans 20,000 square meters, operates 8 advanced production lines, and achieves an annual output exceeding 96,000 tons—providing robust supply capabilities for high‑volume orders.