In addition, nonwoven are highly breathable and have moisture wicking properties, allowing them to be used in a variety of applications such as medical and hygiene products, agricultural solutions, construction materials, and more. These materials are also very flexible and can be easily customized to create a unique good suited to the end customer making them easier to flow through the supply chain. Nonwoven fabrics are an ideal material to supply for the disposable medical market or as a cost-effective, reliable alternative for environmentally friendly shopping bag manufacturers.

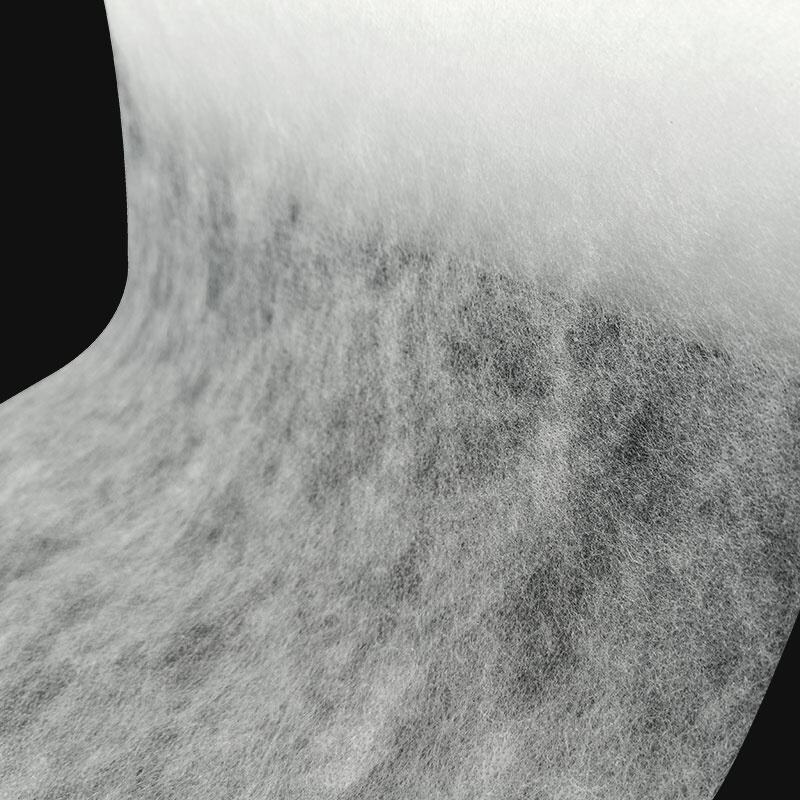

Nonwoven fabrics have changed the game in textile manufacturing, as they provide creative solutions to conventional woven fabric. Produced without a weaving or knitting process, nonwovens are manufactured instead through other methods, and thus offer value for money solutions to the textile industry. Such fabrics are made by bonding or felting together fibers to form a fabric having tensile strength and resistance to abrasion while being capable of utilization for many different purposes.

Versatility and Adaptability One of the primary ways nonwoven fabrics are changing the face of the textile industry is through their remarkable flexibility. These clothes can also be personalized to satisfy certain requirements, i.e. other colors and patterns, etc. This flexibility makes it possible to produce a variety of articles including fabrics and upholstery, filters and geotextiles. In addition, the non-woven fabric is eco-friendly and recycle which are environmentally friendly products for consumers and industries.

Xingdi high quality nonwoven fabric provides excellent support for wholesalers and retailers, making a wide variety of benefits from the textile industry. Featuring a weighted 3D knitted design, allowing the material to be lightweight, long-lasting, customizable and infinitely recyclable. For packaging, clothing or industrial – The wholesale industry still favours nonwovens as the innovative and sustainable material.

Such nonwoven materials are known for a wide variety of end uses in everyday products. They have application in health care, automotive, agriculture and construction industries. In dry health care, the nonwoven textiles are used for surgical drapes, masks and wound dressings to offer liquid-protection and bacteria protection. Car upholstery and insulation are the use of non-woven clothes in automotive industry. Farm uses include crop protection and ground covers. In building and construction, nonwovens also are used in insulation and roofing as well in civil engineering that includes roads/driveways, railways/embankments, airfields/runways offering excellent drainage is a use of nonwoven fabric. The applications of nonwoven materials are numerous and ever increasing as technology continues to advance.

The demand of buyers is high for nonwoven woven fabrics. For one, because they are not as expensive as many woven fabrics, manufacturers with an eye on production cost-cutting may be lured to the prospect of using them. Second, the non-woven fabric is light in weight and can breathe freely, so wearing it is very comfortable. They are also quite easy to clean and will not tarnish, which is why they are a favorite for reusable items. Besides, nonwoven fabrics are very versatile and can be specially designed to possess specific properties, for example, water resistance, flame retardancy and antimicrobicrobial property. These properties have attracted attention of various industries and consumers seeking for nonwoven fabrics.

Are nonwoven fabrics environmentally friendly? It is the category of fabric, and nonwoven fabrics are made from recycled material, so if you're into using products that don't contribute to piling up landfill waste then this is definitely a good option. But then you need to examine the specific manufacturing process and materials of a nonwoven product in order to ascertain its environmental impact.

As a recognized provincial high‑tech enterprise, we focus on medium‑to‑high‑end PP spunmelt non‑wovens, utilizing Japanese‑sourced spinnerets and German calendering technology to produce premium‑grade SS, SMS, SMMS, and multi‑layer fabrics.

In 2021, we launched a new 3.2‑meter SSSS production line with an annual capacity of 12,000 tons, enabling the manufacture of ultra‑fine, multi‑layer fabrics tailored for high‑end sanitary, medical, and hygiene applications.

With over 12 years of industry experience, our facility spans 20,000 square meters, operates 8 advanced production lines, and achieves an annual output exceeding 96,000 tons—providing robust supply capabilities for high‑volume orders.

Our quality control is supported by in‑line monitoring instruments and precision testing equipment—including fiber‑size analyzers, electronic water‑penetration meters, strength testers, and wear testers—ensuring every batch meets stringent performance and consistency standards.