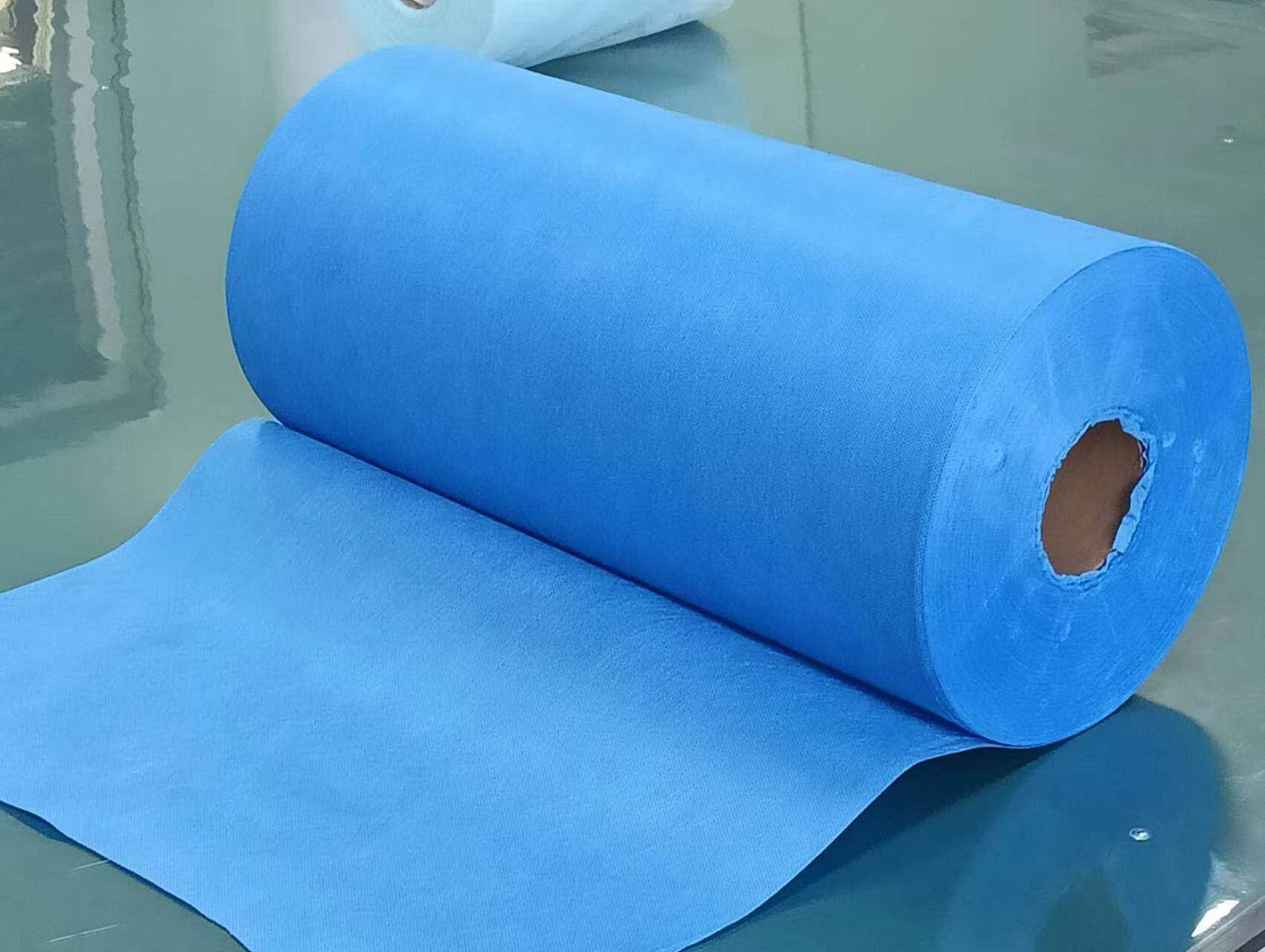

Breathable nonwoven fabric, such as Xindgi's breathable non woven, has many advantages over normal fabirics. These materials are free-breathing and they can be very comfortable to wear for any number of other applications as well. Whether it is industry, medical or beauty; from healthcare to fashion, breathable non woven fabric has developed into a trend.

Breathable non woven fabric is a new type of environmentally-friendly material. Is a good material for the production of textile fabrics. The fabrics made from this material have good hand (handle), light weight, comfort to wear and is suitable for garment,masks and medical products. That’s why this type of fabric is breathable and air flows through, making the wearer feel cool in hot weather. Plus, breathable non woven fabrics keep skin dry and increases comfort. In the health sector, these materials are used in surgical gowns, masks or wound dressings to offer protection while enabling access to oxygen at skin level. All in all, breathable non woven fabric by far has a wider range of applications especially in the garments industry.

Things to Look for In Breathable Non Woven Fabric Wholesale Supplier When searching for a wholesale provider for breathable non woven fabric, there are some things you need to consider in order to obtain the very best quality. First, choose a supplier, such as Xingdi, you trust who is known for its high-quality fabric. # Check the supplier's duration on the market and how reliable products they have provided. You should also ask to see the production of fabrics and control points in order that you can be sure that the quality of fabric meets your requirements. Also consider the pricing and M.O.Q (Minimum Order) of the supplier’s to ensure they can accommodate your business needs. By doing some extensive research and selecting a quality wholesale supplier, you can feel confident that your breathable non woven fabric is the best for what you need.

Breathable non-woven fabric commonly used as a material in different industries. Breathable non woven fabric is widely used in the medical industry. It is commonly used for making surgical masks, gowns and other protective clothing because of its feature allowing air to pass through while blocking liquid and particles. This practice reduces risk for health care providers and prevents cross-contamination to patients.

Agriculture is another sector which takes advantage of breathable non woven fabric. This is the cloth covering you need to protect your plants precisely; Plants can be covered all the year round from rodents, birds, pests, deer, rabbits and other animals. Because the material breathes, air and water pass through naturally to facilitate healthy growth while providing plenty of coverage.

In the packaging industry, breathable non woven fabric is applied to package stuffs so that they need storage or transport. Because the material is breathable, it won't retain moisture that could damage some products. Therefore, it’s a perfect choice of material for packaging fruits, vegetables, and flowers.

One of the key benefits to using breathable non woven material as opposed to traditional, preserved materials is airflow, ability to balance pressure and keep protection while still ensuring high levels of comfort. Not like plastic or rubber fabrics, non woven is more breathable and will not cause skin allergies due to its air permeability. Non woven fabric is also lightweight and versatile, making it cost effective to utilize as a business.

With over 12 years of industry experience, our facility spans 20,000 square meters, operates 8 advanced production lines, and achieves an annual output exceeding 96,000 tons—providing robust supply capabilities for high‑volume orders.

As a recognized provincial high‑tech enterprise, we focus on medium‑to‑high‑end PP spunmelt non‑wovens, utilizing Japanese‑sourced spinnerets and German calendering technology to produce premium‑grade SS, SMS, SMMS, and multi‑layer fabrics.

In 2021, we launched a new 3.2‑meter SSSS production line with an annual capacity of 12,000 tons, enabling the manufacture of ultra‑fine, multi‑layer fabrics tailored for high‑end sanitary, medical, and hygiene applications.

Our quality control is supported by in‑line monitoring instruments and precision testing equipment—including fiber‑size analyzers, electronic water‑penetration meters, strength testers, and wear testers—ensuring every batch meets stringent performance and consistency standards.