One of the principal advantages of hydrophilic spunbond is its water uptake rate and absorbency. This makes it a great material for products that must remain dry to be comfortable like baby diapers and feminine hygiene products. Spunbond hydrophilic is also soft hand feeling, smooth for touching, nice and gentle to skin, ideal material for medical drapery and wound care.

Yet another benefit of hydrophilic spunbond is its strength and durability. Very thin and very lightweight, yet extremely durable--a wonderful material that can be used for almost any application. Spunbond as hydrophilic material, may withstand the average wear and tear of daily use without breaking down, whether its part of medical supplies or a filtration system.

Moreover, the hydrophilic spunbond is breathable with air passage therethrough. This is helpful for counteracting skin irritations, chafing and itching, making it a good candidate for items that are worn directly against the skin. Whether it’s for personal care items or medical disposables, hydrophilic spunbond allows for body comfort and ensures that both the wearer and non-wearer will be kept safe.

Get to know about Hydrophilic Spunbond Manufacturer As far as when you are looking for a hydrophilic spunbond supplier, you need to ensure the quality of the materials these companies are supplying. Xcxf Xingdi hydrophilic spunbond is a well-known fabric brand, The hydrophilic nonwoven fabric is specially used for baby's and adult's diaper, with the excellent super high soft quality. Being in this fine industry for ages, and being obsessed with the highest quality — at Xingdi, all products are meticulously made!

Production capacity and reliability are another options that would need to be considered when selecting as a hydrophilic spunbond manufacturer. State of the art facilities xingdi has a factory with state-of-the-art machinery capable of delivering large quantities of materials quickly and on time. Xingdi listens and understands the need of their customers by working together with them to develop final solutions for each specific customer.

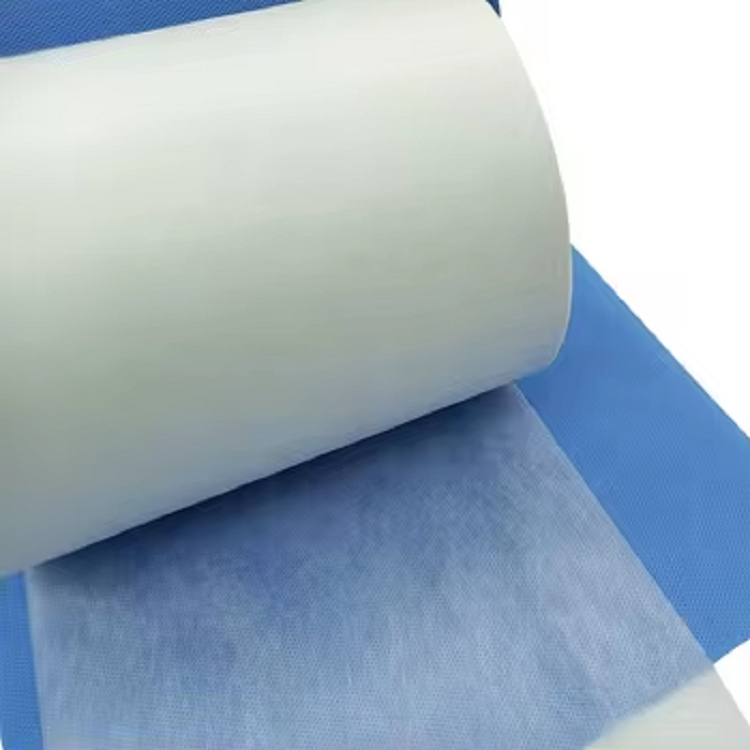

Hydrophilic spunbond material with the capability of rapidly absorbing and retaining liquid is desirable in absorbent articles. The material is made from synthetic fibers, processed to generate a wealth of tiny pores that are able to attract and capture water; it can be used in products such as diapers, sanitary towels and medical dressings. Xingdi hydrophilic spunbond can effectively absorb the liquid, making the skin dry and comfortable. It is highly absorbent and has a soft feel, making it ideal for manufacturers to craft leaking products that offer excellent absorption and keep users comfortable.

One of the good properties of the hydrophilic spunbond is excellent absorption than the other materials. Unlike conventional and nonwoven fabrics, hydrophilic spunbond has been engineered to wick and hold liquid superior with moisture pickup. What’s more, Xingdi hydrophilic spunbond is air permeable for all day comfortable wear, and the softness on the skin minimizes the chances of irritation or redness. It is also easy to cut and shape, so manufacturers can use it in various products, making it a flexible option for those who are trying to develop absorbent products that are high-performing yet comfortable.

As a recognized provincial high‑tech enterprise, we focus on medium‑to‑high‑end PP spunmelt non‑wovens, utilizing Japanese‑sourced spinnerets and German calendering technology to produce premium‑grade SS, SMS, SMMS, and multi‑layer fabrics.

In 2021, we launched a new 3.2‑meter SSSS production line with an annual capacity of 12,000 tons, enabling the manufacture of ultra‑fine, multi‑layer fabrics tailored for high‑end sanitary, medical, and hygiene applications.

Our quality control is supported by in‑line monitoring instruments and precision testing equipment—including fiber‑size analyzers, electronic water‑penetration meters, strength testers, and wear testers—ensuring every batch meets stringent performance and consistency standards.

With over 12 years of industry experience, our facility spans 20,000 square meters, operates 8 advanced production lines, and achieves an annual output exceeding 96,000 tons—providing robust supply capabilities for high‑volume orders.