Non woven polypropylene geotextile is the most cost-effective method for preventing erosion and stabilizing soil. This is a tough durable material that will ideally protect erosion control on slopes or hills. It also can act as a soil stabilizer in construction projects, roadways and landscaping. Xingdi manufactures non woven polypropylene geotextile of high quality with good durability. Check out our 45gsm 1600mm PP SMS SMMS Spunbond Nonwoven Fabric for Surgical Clothing.

PPGE Felt Polypropylene Geotextile Nonwoven 20' x 300' Polypropylene Material Tyco -GPET012-FIRST 10´ OF THE FIRST NONWOVEN FUNCTION ERECTED-Drawing: SKGPET012-08)2.1 F Product Description and Intended Use The PPGE gasket is a cost-effective product used for erosion control and soil stabilization applications. You can avoid soil erosion and the ground will also be more stable with the use of this material. This is particularly beneficial in heavily irrigated regions that tend to be eroded. Xingdi nonwoven polypropylene geotextile is most often used to protect fine subgrades from mixing with the aggregate. Use this material to defend your territory and material without needing to spend all of your money. Explore our Anti-Static 42g 43g SMS SMMS PP Spunbond Nonwoven Fabric for Hospital Uniform.

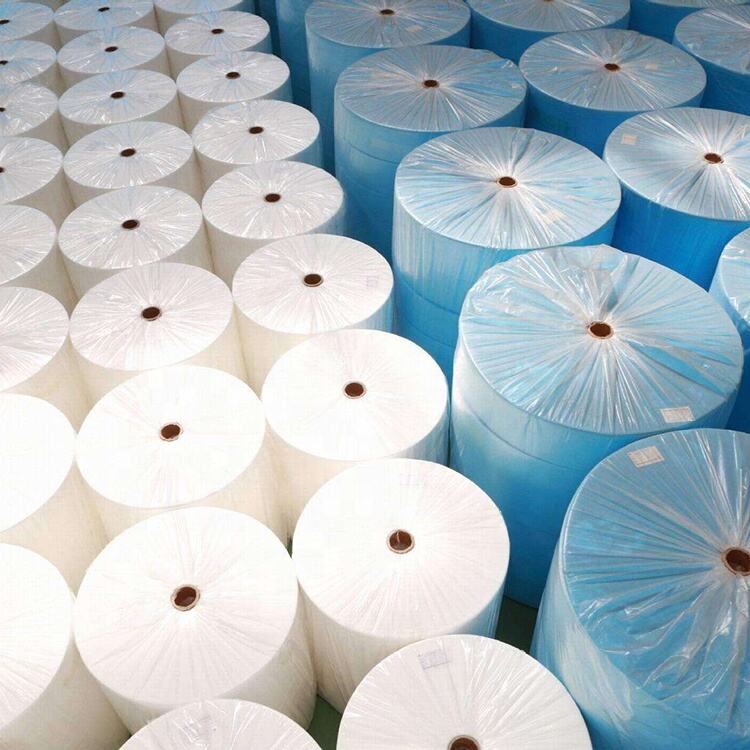

If you would like to buy non woven polypropylene geotextile in large quantity, Xingdi is the ideal place. Our company provides a premium geotextile that is ideal for use in erosion control and soil stabilization applications. Whether it’s a large colonial job or just a few rolls for a small project Xingdi can get you the material you need. By the virtue of bulky purchase from Xingdi, you can get more competitive geomembrane price and surplus geotextile to guarantee that your project is well finished. Discover our Water Repellent 100%PP Spunbond SMS SMMS Nonwoven Fabric for Surgical Clothing.

Is non woven polypropylenegetextile recyclable after use?

The Advantages of Non Woven Polypropylene Geotextile: It can be recycled. Once it has performed its usefulness in a construction or landscaping application, the geotextile can be recovered and delivered to a recycling facility. Here it can be refined and repurposed into new materials, saving landfill space and aiding the environment. When you opt to incorporate recyclable products like non woven polypropylene geotextile, you help the construction industry become more sustainable and environmentally friendly.

In 2021, we launched a new 3.2‑meter SSSS production line with an annual capacity of 12,000 tons, enabling the manufacture of ultra‑fine, multi‑layer fabrics tailored for high‑end sanitary, medical, and hygiene applications.

With over 12 years of industry experience, our facility spans 20,000 square meters, operates 8 advanced production lines, and achieves an annual output exceeding 96,000 tons—providing robust supply capabilities for high‑volume orders.

As a recognized provincial high‑tech enterprise, we focus on medium‑to‑high‑end PP spunmelt non‑wovens, utilizing Japanese‑sourced spinnerets and German calendering technology to produce premium‑grade SS, SMS, SMMS, and multi‑layer fabrics.

Our quality control is supported by in‑line monitoring instruments and precision testing equipment—including fiber‑size analyzers, electronic water‑penetration meters, strength testers, and wear testers—ensuring every batch meets stringent performance and consistency standards.