Xingdi – Manufacturer of Non Woven Fabric _) Some Common Applications of Non Woven Fabric •Hygiene: baby diapers, adult incontinence products and feminine hygiene. •Medical: Surgery gowns, disposable bed sheets and curtains etc. •Packing: Shopping bags, garment bag and shoe bags. •Work Protection accessories: protective clothing for sewing, mine drilling projects oil & gas exposures etc. •Automotive: Headliners, door panels, seat covers and carpet protection. Non woven fabric production methods are sustainable, eco-friendly and innovative while matching the quality and efficiency of non-wovens.</p>

Xingdi adheres to sustainable and environmentally friendly production traditions for non woven fabric. This includes being mindful of our waste, using recycled material and limiting the application of harmful chemicals. In this way, Xingdi serves to minimize its ecological footprint and provide customers with a greener product.</p>

Xingdi also employs advanced technology of non woven fabric manufactures, the environmentally friendly process. These include state-of-the-art equipment, computerized processes, and stringent quality control to make certain that every yard of cloth meets our high expectations. Keeping the leading developments in technology and products is what Xingdi provides to its customers in all industries.</p>

Xingdi’s Vision is to be the best choice to manufacture non woven fabric.Product sTablecloth Material Printed Non Woven Table Cloth At Best PricePrinting & PackagePaper tube package or OPP bag with a labelCorlorful High Quality Printed Spunbond Nonwoven Fabric TNTTablecloth In 40gsm For Weeding Party Owning advanced equipment and nature technology, we can assure you the good quality and excellent design of our products. By emphasizing quality, efficiency and environmentally-conscious operation, Xingdi is ready to offer top quality products to its customers around the world.</p>

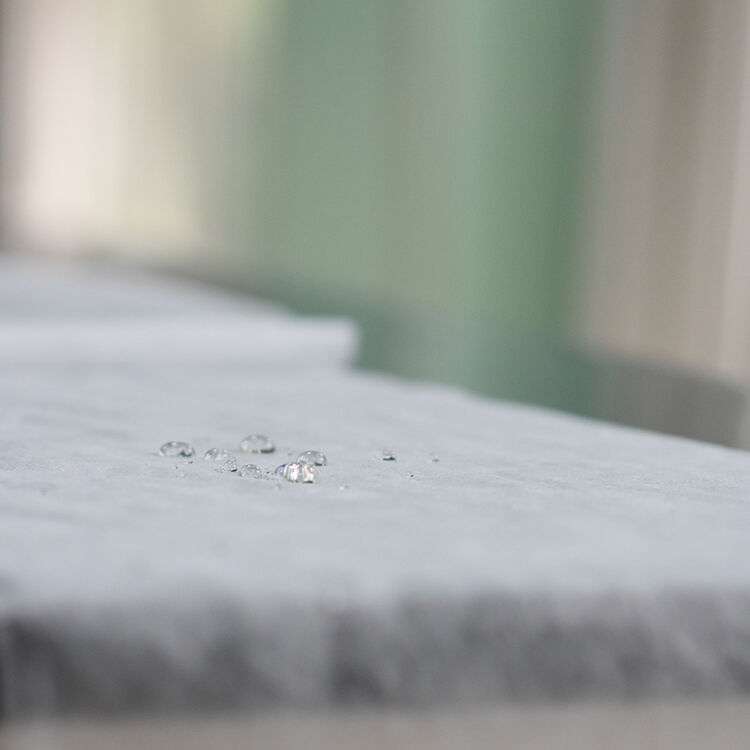

Non Woven fabric is a fabric-like material made from long fibers, bonded together by chemical, mechanical, heat or solvent treatment. Non woven fabric is used in numerous such markets as surgical mask, select gowns, caps and other products, but its primary use in barrier protection is for the patient. Agriculture Non Woven Fabric adds the stability and the water permeability features on top of its various industrial application. Nonwoven fabric is also used in automobile for interior upholstery, insulation, and filtering. In the construction business, including insulation and roofing it can be used as a protective barrier for packing chemicals like asbestos, acid and alkali.</p>

When you need to find a non woven fabric supplier for your business, there are some things that you should take into consideration so that you can make sure that you are getting the best quality products. 1) You should inquire and check about the reputation of the provider and how long it has been in business. Find a manufacturer with a history of providing customers top quality non woven fabric. You should also look into the product catalog which they have and see if there’s something suitable for your needs. You also need to look at what the supplier is offering in terms of pricing and delivery so that you know that you are getting the best deal that your money can buy.</p>

Our quality control is supported by in‑line monitoring instruments and precision testing equipment—including fiber‑size analyzers, electronic water‑penetration meters, strength testers, and wear testers—ensuring every batch meets stringent performance and consistency standards.

As a recognized provincial high‑tech enterprise, we focus on medium‑to‑high‑end PP spunmelt non‑wovens, utilizing Japanese‑sourced spinnerets and German calendering technology to produce premium‑grade SS, SMS, SMMS, and multi‑layer fabrics.

With over 12 years of industry experience, our facility spans 20,000 square meters, operates 8 advanced production lines, and achieves an annual output exceeding 96,000 tons—providing robust supply capabilities for high‑volume orders.

In 2021, we launched a new 3.2‑meter SSSS production line with an annual capacity of 12,000 tons, enabling the manufacture of ultra‑fine, multi‑layer fabrics tailored for high‑end sanitary, medical, and hygiene applications.