SMS material is mainly used in key areas of diaper coverings such as core covering, leak-proof side panels, and front and back waistbands. With its composite structure of "spunbond + meltblown + spunbond", it balances barrier properties, strength, breathability, and softness, meeting the stringent requirements of hygiene products.With a professional management team and more than ten years of production experience, Shandong Xingdi New Material Co.,ltd can produce and supply high quality water repellent, hydrophilic, super soft, elastic, and perforated non-woven fabrics.

|

Product Name |

SMS Nonwoven Fabric |

|

Material |

100% PP(polypropylene) |

|

Technique |

Spunmelt nonwoven fabric |

|

Weight |

10g-25g |

|

Width |

160-350mm |

|

Roll Length |

Depend on your request |

|

Color |

As your requirements |

|

Feature |

Highly hydrophilic,Water repellent,Soft and skin-friendly,High strength |

|

Soft Type |

Normal Soft.,Super Soft,Cotton Soft,Silk Soft |

|

Application |

Core Wrap,Leg Cuff,Front and back waist patches / ear patches,Back Sheet |

· Barrier & Leak-proof Performance

The ultra-fine fibers (2–5 μm) of the meltblown layer form a dense network with a hydrostatic pressure resistance of 500–1500 mmH₂O, effectively blocking liquid and micro-particles, and significantly reducing leakage and rewetting.

· Strength & Durability

The double spunbond layers provide high tensile and tear strength, withstanding mechanical stress during diaper processing and use, reducing breakage and core displacement.

· Breathability & Comfort

The porous structure of spunbond layers ensures air circulation. Combined with precise hydrophilic/water-repellent modification, it achieves "liquid-proof without stuffiness" and reduces the risk of diaper rash.

· Safety & Compatibility

Made of 100% polypropylene (PP), it contains no fluorescent agents or formaldehyde, complies with SGS/MSDS/ISO certifications, and has low sensitization. It can be permanently modified to be hydrophilic or water-repellent, adapting to the functional requirements of different parts.

|

Application Part |

Functional Positioning |

Treatment & Grammage |

Key Functions |

|

Core Wrap |

Encapsulates fluff pulp and SAP to prevent leakage and penetration |

Hydrophilic modification, 10–15 g/m² |

Replaces dust-free paper; offers high tensile strength, prevents core shifting, agglomeration, and delamination; blocks SAP leakage |

|

Leg Cuff |

Blocks liquid around leg openings |

Water-repellent / high hydrostatic pressure resistance,12–20 g/m² |

20 g/m²Dense meltblown layer stops liquid; spunbond layers maintain shape and wear resistance; reduces side leakage risk |

|

Front/Back Waist Tabs/Ear Tabs |

Blocks liquid around leg openings |

Water-repellent /tear-resistant, 15–25 g/m² |

High tensile strength and fatigue resistance; resistant to breakage after repeated adhesion; improves wearing stability |

|

Back Sheet Lamination |

Anti-seepage and breathability |

Laminated with water-repellent & breathable film, 15–30 g/m² |

Blocks urine while allowing moisture vapor transmission; balances dryness and breathability |

Q1: Is the softness of SMS nonwoven fabric sufficient for the diaper top layer?

A1: It's sufficiently adaptable, and its softness can be further improved through process optimization. We currently offer 5-6 levels of softness for you to choose from.

Q2: Does your 100% PP SMS spunbond nonwoven fabric roll for diapers meet international hygiene standards?

A2: Yes, it fully complies. Our SMS is made from 100% PP raw materials and has passed ISO, SGS, and MSDS testing and certification, fully meeting the safety requirements for infant hygiene products.

Q3: Can the absorbency of the product be customized?

A3: Of course. Depending on your specific application scenario (surface layer/ absorbent layer), we can adjust the parameters of the hydrophilic modification process to customize products with different absorbency rates to meet your personalized production needs.

Q4: Do you provide free sample testing?

A4:Yes, we provide 3-5 square meters of free samples, which will be shipped within 24 hours. We can also provide quality inspection reports according to your requirements, covering key indicators such as basis weight, tensile strength, and absorbency,and hydrostatic pressure.

Q5: What is the minimum order quantity (MOQ) and delivery time?

A5: The minimum order quantity is 1000 kg. Shipment will be made within 5-7 business days after payment. We can ensure a stable and continuous supply for large-volume orders.

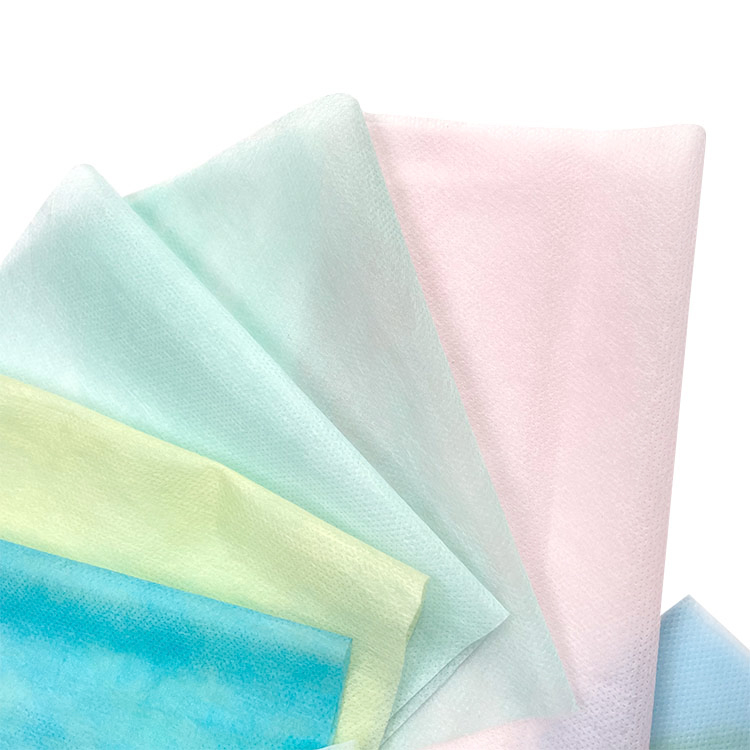

Q6: Can the 100% PP SMS nonwoven fabric rolls be customized in color?

A6: Yes. We can customize various colors such as white, blue, and pink according to your brand requirements, with a color difference of ≤±2%, meeting the differentiated design needs of end products.

Shandong Xingdi New Material Factory has three spunbond nonwoven production lines and one PP/PE laminated production line with a total annual capacity of 35,000 tons. Drawing on advanced and cutting-edge technologies from numerous domestic and foreign manufacturers, our production lines can produce and supply SS, SSS, SSSS, SMS, SMMS, and PP/PE laminated nonwovens in any color. Our nonwoven material is 100% PP, possessing excellent fiber fineness, high hydrostatic pressure resistance, and uniform sesame spots. In the future, Shandong Xingdi New Material Sanitary Napkin Corporation will keep pace with the times, continuously innovating, satisfying customer needs, and growing together with our customers!

For free samples, detailed quotations, or technical parameter manuals, please contact us through the following methods: submit an inquiry online (click the "Inquiry" button below), or call our hotline: +86 155 5370 9566 Alternatively, you can send an email to [email protected]. We will respond to your request within one hour and look forward to cooperating with you for a win-win situation!